In today’s competitive and unpredictable global market, cost optimization is no longer just an operational goal—it’s a strategic necessity. With supply chain disruptions, rising input costs, and increasing customer expectations, businesses need efficient and agile supply chain strategies to stay ahead.

Below are the top 10 proven strategies supply chain leaders can use to reduce costs while improving performance, sustainability, and long-term value.

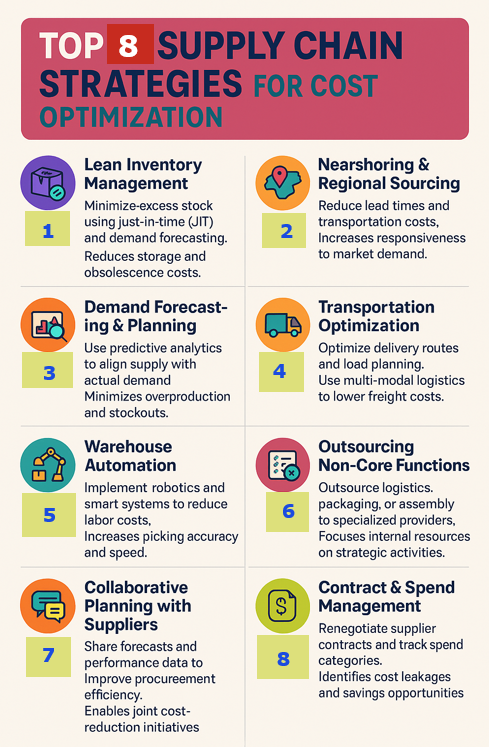

1. Lean Inventory Management

One of the most impactful ways to cut costs is by minimizing excess stock. Applying Just-in-Time (JIT) inventory systems and accurate demand forecasting helps avoid overstocking and understocking. This reduces storage expenses, lowers the risk of obsolescence, and improves cash flow.

Benefit: Reduced carrying costs, better inventory turnover, and increased working capital.

2. Nearshoring & Regional Sourcing

Long global supply chains are vulnerable to delays, tariffs, and disruptions. By sourcing materials or manufacturing closer to the point of consumption, companies reduce freight costs, lead times, and carbon footprint.

Benefit: Greater agility, lower transportation expenses, and better market responsiveness.

3. Warehouse Automation

Modern warehouses are embracing robotics, conveyor systems, and AI-driven inventory tracking to boost efficiency. Automation reduces human error, speeds up fulfillment, and cuts down labor costs.

Benefit: Lower operational costs and improved order accuracy.

4. Transportation Optimization

Efficient transportation plays a critical role in cost control. Using route optimization software, load consolidation, and multi-modal logistics ensures faster, more economical deliveries.

Benefit: Reduced fuel expenses, fewer delays, and lower freight costs.

5. Demand Forecasting & Planning

Poor forecasting can result in high stockouts or excess inventory. By integrating sales data, market trends, and AI-powered tools, businesses can improve forecast accuracy and align procurement and production accordingly.

Benefit: Balanced inventory, reduced waste, and improved service levels.

6. Outsourcing Non-Core Functions

Focus on your core competencies by outsourcing functions like packaging, freight management, or assembly to specialized third-party providers. This helps reduce overheads and improves process flexibility.

Benefit: Reduced fixed costs and access to specialized expertise.

7. Collaborative Planning with Suppliers

Supply chain success depends on transparency and alignment. Sharing forecasts, demand data, and production schedules with suppliers ensures better synchronization and allows for joint cost-saving initiatives.

Benefit: Improved procurement efficiency and stronger supplier partnerships.

8. Contract & Spend Management

Unmanaged contracts can hide inefficiencies and missed savings. Implementing robust spend analysis and contract lifecycle management tools helps organizations identify overspending and renegotiate terms.

Benefit: Cost visibility, compliance, and better supplier performance.

Summary Table

| Strategy | Key Focus | Cost Impact |

|---|---|---|

| Lean Inventory | Reduce excess stock | ↓ Holding costs |

| Vendor Consolidation | Fewer suppliers | ↓ Procurement cost |

| Nearshoring | Local sourcing | ↓ Freight & delays |

| Automation | Robotics/AI | ↓ Labor costs |

| Transport Optimization | Route planning | ↓ Logistics costs |

| Forecasting | Demand analysis | ↓ Stockouts & overstocking |

| Outsourcing | Third-party services | ↓ Overheads |

| Collaboration | Supplier alignment | ↓ Process waste |

| Contract Management | Spend visibility | ↓ Leakage |

| Sustainability | Green practices | ↓ Waste & energy |

Final Thoughts

Optimizing your supply chain costs doesn’t require drastic changes—it needs strategic choices and technology-driven execution. These ten strategies offer a holistic approach to not just lowering expenses, but also building a more resilient, agile, and competitive supply chain.

As global sourcing becomes more complex, cost control must go hand-in-hand with sustainability, innovation, and supplier collaboration. Companies that prioritize these principles will be better prepared for future disruptions and poised for sustainable growth.

Frequently Asked Questions (FAQs)

Q1. What is the biggest cost driver in supply chains?

A: Inventory carrying costs, transportation, and supplier inefficiencies are typically the largest contributors.

Q2. How can small businesses reduce supply chain costs?

A: By adopting lean inventory practices, consolidating suppliers, and leveraging local sourcing and digital tools.

Q3. Is automation affordable for mid-sized businesses?

A: Yes, cloud-based warehouse systems, barcode scanners, and modular robotics have made automation more accessible.

Q4. Why is sustainability important in cost optimization?

A: Sustainable practices reduce waste and energy use, which in turn reduces operational expenses while boosting brand image.

Author’s Bio:

Pankaj Tuteja

Head of Operations – India

https://www.dragonsourcing.com