Summary:

- Global sourcing success depends on balancing cost efficiency and product quality.

- Set clear quality benchmarks before sourcing.

- Evaluate total cost of ownership, not just unit price.

- Diversify suppliers to minimize risks.

- Conduct regular supplier audits to ensure compliance.

- Use AI and blockchain for real-time transparency.

- Build long-term supplier partnerships for reliability.

- Negotiate win-win deals to sustain quality.

- Track KPIs like defect rate and delivery time.

- Combine local and global sourcing for optimal results.

It’s now a constant process to find the perfect balance between cost efficiency and quality assurance in the interconnected global marketplace by the companies. International suppliers can offer significant savings while sourcing; the challenge lies in maintaining consistent quality across regions and suppliers. The great and successful companies understand that global sourcing isn’t just about buying cheap; it’s about creating long-term value through strategic supplier partnerships, risk management, and innovation.

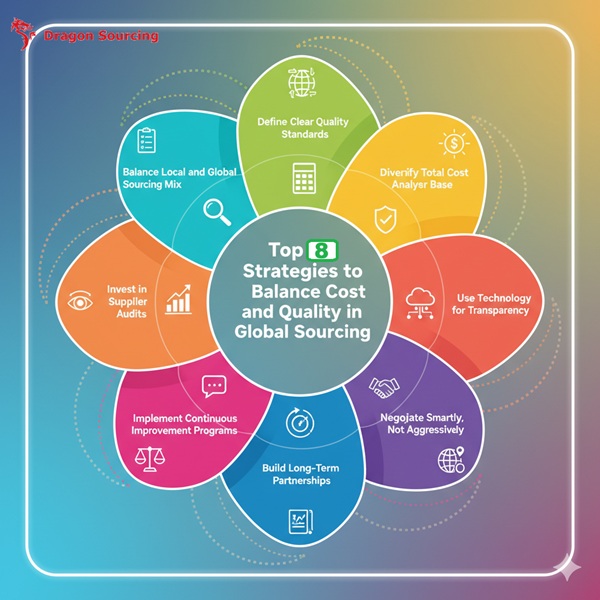

Here are the top 10 strategies to help businesses strike the right balance between cost and quality in global sourcing.

Define Clear Quality Standards

Create detailed and measurable quality benchmarks before starting any sourcing project. Define detailed product specifications, acceptable tolerances, and inspection protocols. It helps suppliers understand expectations and reduces misunderstandings that lead to costly rework or delays.

Conduct Total Cost Analysis

Don’t focus only on unit price, which can be misleading. A total cost of ownership (TCO) includes logistics, customs duties, lead time, quality failures, and hidden risks. Company businesses that evaluate total landed cost make more sustainable and profitable sourcing decisions.

Diversify Supplier Base

Selecting multiple suppliers or countries can lead to disruptions and quality inconsistencies. Extend the supplier network across multiple geographies to mitigate risk and gain access to competitive advantages offered by different markets.

Invest in Supplier Audits

Supplier audits on a regular basis are critical to maintaining consistent quality. Inspect the production facilities, management processes, labor conditions, and compliance with international standards. It builds trust and ensures transparency through continuous auditing.

Use Technology for Transparency

The emerging technologies like AI, IoT, and blockchain are transforming supplier monitoring and quality management. Data collection, especially in real-time data and digital dashboards, allows procurement teams to track performance, detect issues early, and make data-driven sourcing decisions.

Build Long-Term Supplier Relationships

The relationship with a supplier should be strong; it often delivers better results than constantly switching for lower prices. The long-term partnership with the suppliers encourages collaboration, innovation, and mutual commitment to improving both cost efficiency and quality.

Negotiate Smartly, Not Aggressively

A successful negotiation is not about squeezing suppliers but about getting a win-win balance. Suppliers are more motivated to maintain high standards and offer better terms over time when you trust them.

Implement Continuous Improvement Programs

It will be great if you encourage suppliers to adopt lean manufacturing, Six Sigma, and Kaizen methodologies. Do the improvements with the Together programs reduce waste, enhance efficiency, and lower costs without compromising on quality.

Monitor KPIs Regularly

Build measurable Key Performance Indicators (KPIs) like defect rates, on-time delivery, cost per unit, and total landed cost. Data-driven evaluation helps identify improvement areas and maintain accountability throughout the supply chain.

Balance Local and Global Sourcing Mix

Both nearshoring and offshoring help businesses to achieve cost efficiency while maintaining agility. Local sourcing supports quick turnaround and quality oversight, while global sourcing reduces material and labor costs.

Why Balancing Cost and Quality Matters

The right balance between cost and quality isn’t just a procurement goal; it’s a matter of business growth strategy. A good and established balance sourcing approach enhances profitability, strengthens supply chain resilience, and boosts brand reputation. The organization that focuses on long-term value creation rather than short-term cost cutting builds stronger, more sustainable supply chains.

Conclusion

Quality and cost balancing in global sourcing is both an art and a science. By applying these ten strategies, from data-driven decision-making to building trusted supplier partnerships. Companies can gain sustainable growth and maintain a competitive edge in global markets. The key is to think beyond price and focus on value, reliability, and long-term success.

FAQ Section

- What is the biggest challenge in balancing cost and quality in global sourcing?

The biggest challenge in balancing cost and quality is managing supplier consistency across different geographies while ensuring price competitiveness. Quality and cost are both impacted by cultural, regulatory, and logistical variations.

- How can technology help in achieving cost-quality balance?

AI, blockchain, and predictive analytics—such technologies provide real-time insights, enabling better decision-making, transparency, and supplier performance tracking.

- What role does supplier relationship management play in quality control?

Strong relationships foster trust, communication, and collaboration — essential for ensuring suppliers remain committed to meeting quality expectations over time.

- Should companies always choose the lowest-cost supplier?

Not necessarily. The lowest price doesn’t always equal the best value. A higher-priced supplier might offer better reliability, lower defect rates, and reduced total costs in the long run.

- How often should supplier audits be conducted?

Audits should be conducted for the critical suppliers at least once a year. However, continuous digital monitoring can complement physical audits to ensure ongoing compliance.

Resources

- World Economic Forum: Global Supply Chain Resilience Report 2025

- McKinsey & Company: The Future of Procurement in a Digital World

- Harvard Business Review: Balancing Cost, Quality, and Speed in Global Sourcing

- Gartner: Procurement and Supplier Management Best Practices

- Dragon Sourcing Insights: How to Improve Supplier Quality in Global Markets

Author’s Bio:

Pankaj Tuteja

Head of Operations – India

https://www.dragonsourcing.com