Key Takeaway

It is a continuous process to reduce the procurement cost, not a one-time exercise.

By taking data analytics, supplier collaboration, and digital transformation all together, organizations can achieve significant savings without compromising quality or ethics.

In essence, modern procurement cost reduction is about value creation, not cost cutting.

In today’s fragile world economy, the leaders from the procurement field face enormous pressure to deliver savings without compromising quality or supplier relationships. It’s difficult to reduce procurement costs; it is no longer about simply negotiating lower prices, it’s about strategic value creation, data-driven decision-making, and process optimization.

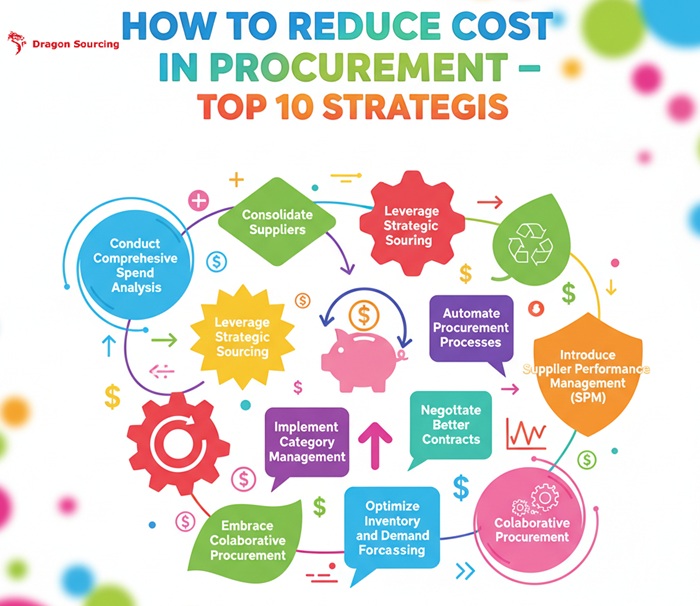

In this blog, we’ll explain the top 10 proven strategies that help organizations cut procurement costs effectively while ensuring long-term resilience and sustainability.

Conduct Comprehensive Spend Analysis

First you have to understand where your money goes. A detailed analysis of spending helps identify inefficiencies, maverick spending, and cost-saving opportunities across departments.

You may use procurement analytics tools or ERP data to:

- Consolidate the spending data from all business units.

- Organize suppliers and products with the value and volume.

- Identify redundant or overlapping suppliers.

Outcome: Enhanced clear idea or visibility into total spend, paving the way for smarter sourcing decisions.

Consolidate Suppliers

Working with many suppliers often means missed opportunities for volume discounts.

By rationalizing your supplier team and closely working with key partners, you can discuss better terms and streamline logistics.

Tip: Build long-term relationships with the best suppliers to unlock additional savings through loyalty and collaboration.

Leverage Strategic Sourcing

Strategic sourcing works beyond price. It checked the total cost of ownership (TCO), including shipping, payment terms, lead time, and after-sales service.

Check the performance of the suppliers based on both cost and value; you can confirm sustainable savings and lower risk exposure.

Automate Procurement Processes

Nowadays, manual procurement processes are time-consuming and error-prone.

E-procurement and the e-procurement platforms and other tools like digital sourcing reduce paperwork, cut administrative costs, and provide real-time insights.

Check the automation benefits:

- Faster purchase order cycles.

- Reduced human error.

- Better compliance and audit trails.

Example Tools: Coupa, SAP Ariba, Precoro, or Jaggaer.

Implement Category Management

The category managers should apply the targeted cost-reduction tactics when the company spends in specific categories (e.g., IT, logistics, raw materials).

Category management raises excellent market knowledge, helps monitor supplier performance, and enhances negotiation power.

Result: Smarter decisions and measurable savings per category.

Negotiate Better Contracts

It’s not the end of procurement cost reduction after supplier selection; contract management is equally critical.

Discuss with flexibility the contracts with clauses for volume discounts, rebates, and performance-based incentives.

Review and renegotiate contracts annually to ensure competitiveness against market benchmarks.

Introduce Supplier Performance Management (SPM)

Check the performance of the supplier regularly using KPIs such as on-time delivery, defect rates, and service quality.

An SPM with the data framework helps you identify high-cost or underperforming vendors and replace them with more efficient alternatives.

Benefit: Continuous improvement and long-term cost savings.

Optimize Inventory and Demand Forecasting

Bringing extra inventory ties up capital and increases storage costs.

Use demand forecasting tools to find the purchasing decisions with actual consumption.

Adopt Just-in-Time (JIT) or Vendor-Managed Inventory (VMI) models, which lower warehousing expenses and waste.

Embrace Collaborative Procurement

Tying up with other companies or departments to aggregate demand can improve buying power.

Like, public institutions often use group purchasing organizations (GPOs) to achieve economies of scale.

Private firms can use similar styles for shared categories like logistics, IT, or office supplies.

Incorporate Sustainable Procurement

While the sustainability initiatives may be costly upfront, they often result in long-term cost efficiency.

Near sourcing, choosing energy-efficient suppliers, and reducing waste all contribute to both cost savings and corporate responsibility goals.

Bonus: Sustainable procurement increases brand reputation and regulatory compliance.

FAQ

Q1: What is the easiest way to start reducing procurement costs?

First do the spend analysis. It shows a clear picture of where cost savings can be made quickly through supplier consolidation, contract renegotiation, or process automation.

Q2: How does technology help in procurement cost reduction?

E-procurement platforms help in many ways to do the automated routine tasks, minimize errors, and enable better data visibility — all of which reduce operational costs and improve supplier negotiations.

Q3: Is cost reduction the same as cost avoidance?

No. Procurement cost reduction works to reduce current expenses, while cost avoidance means stop working the future costs (e.g., choosing energy-efficient equipment to avoid future energy expenses).

Q4: Can sustainability and cost reduction go hand in hand?

Yes, sustainability helps reduce the costs through energy efficiency, waste reduction, and improved supply chain resilience.

Resources

- CIPS (Chartered Institute of Procurement & Supply) – Procurement Cost Reduction Techniques

- Deloitte Insights – Global Chief Procurement Officer Survey 2025

- Spend Matters – Digital Procurement and Automation Strategies

- McKinsey & Company – Smart Procurement: The Next Generation

- Supply Chain Dive – Procurement Trends 2025

Author’s Bio:

Pankaj Tuteja

Head of Operations – India

https://www.dragonsourcing.com