Key Takeaways

- AI-based software and tools are transforming every layer of supply chain operations, from planning to procurement.

- Organizations implementing tools like Blue Yonder, Llamasoft, and Interos gain real-time insights and operational agility.

- Putting the money and time in AI isn’t optional anymore; it’s essential for global competitiveness and resilience.

- The future supply chain will be predictive, autonomous, and sustainable—and AI is the catalyst behind it.

In this growing global economy, supply chain management (SCM) has usually gone through a radical transformation with the help of Artificial Intelligence (AI). There are many segments, from demand forecasting and inventory optimization to supplier risk management and logistics, where AI-powered tools are helping the organizations become smarter, more efficient, and more resilient.

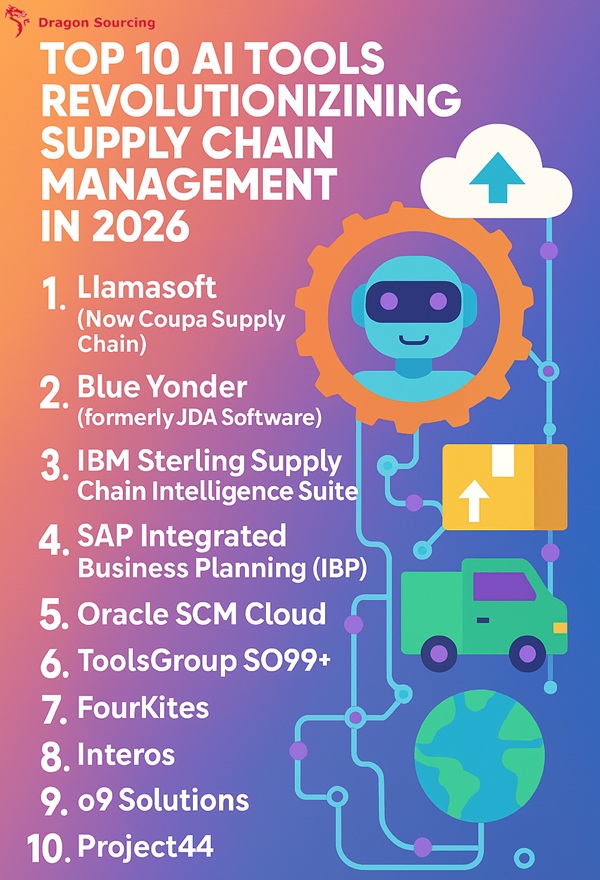

For procurement and sourcing experts, working with the right AI tools can mean the difference between a reactive operation and a proactive one for the data-driven enterprise. We explore in this blog the top 10 AI tools every supply chain management company should adopt in 2026.

Llamasoft (Now Coupa Supply Chain)

Use Case: Design the supply chain, optimization, and simulation.

Key Benefit: Helping companies to build digital twins of their supply chains, test “what-if” scenarios, and take smarter network decisions.

AI Edge: Future predictive modeling and modern machine learning for strategic sourcing, demand planning, and transportation optimization.

Blue Yonder (formerly JDA Software)

Use Case: From top to bottom supply chain planning and execution.

Key Benefit: Forecasting, replenishment, and logistics planning in real time by AI-based power.

AI Edge: Work in cognitive analytics to predict disruptions and adjust production schedules automatically.

IBM Sterling Supply Chain Intelligence Suite

Use Case: Visibility and risk management

Key Benefit: The services are end-to-end visibility and collaboration between suppliers, logistics providers, and manufacturers.

AI Edge: Watson AI detects anomalies, predicts delays, and recommends optimal resolutions through prescriptive analytics.

SAP Integrated Business Planning (IBP)

Use Case: Demand, inventory, and supply optimization.

Key Benefit: With the help of AI and real-time data to work on the supply and demand across global operations.

AI Edge: Predictive algorithms find the changes in consumer behavior and forecast demand more accurately.

Oracle SCM Cloud

Use Case: Digital transformation of supply chain operations.

Key Benefit: Creates a unique platform for procurement, logistics, and manufacturing.

AI Edge: AI, machine learning does the routine tasks automatic like supplier scoring and delivery scheduling, improving overall responsiveness.

ToolsGroup SO99+

Use Case: Demand forecasting and inventory optimization.

Key Benefit: It helps to prevent stock-outs and overstocking through probabilistic forecasting.

AI Edge: Can educate from historical patterns and external factors (e.g., weather, promotions) to refine forecasts dynamically.

FourKites

Use Case: Real-time transportation visibility.

Key Benefit: Tracks shipments from the global market and predicts estimated times of arrival using AI.

AI Edge: Integrates IoT data and predictive analytics to decrease the delays and improve customer satisfaction.

Interos

Use Case: Supplier risk and resilience management.

Key Benefit: Check and engage with multi-tier supplier networks for risk factors like geopolitical tension, financial instability, or ESG non-compliance.

AI Edge: Work with graph-based AI to map entire supplier ecosystems and flag potential vulnerabilities in real time.

o9 Solutions

Use Case: Integrated business planning and decision-making.

Key Benefit: Helps the companies AI-driven scenario planning and demand sensing.

AI Edge: The tool “Digital Brain” continuously learns from internal and external data to optimize planning and forecasting decisions.

Project44

Use Case: Supply chain visibility and predictive logistics.

Key Benefit: Provides real-time insights into shipment status and predictive ETAs.

AI Edge: Work in machine learning to identify transportation bottlenecks and suggest alternative routes or carriers.

Why AI Matters in Supply Chain Management

AI is now entered into supply chain management activities; it’s the backbone of modern SCM. Here’s why adopting AI tools is mission-critical:

- Increased Forecast Accuracy: AI work with real-time data and predictive analytics to minimize errors.

- Risk Mitigation: AI constantly checking supplier networks for early signs of disruption.

- Cost Reduction: Automation and futuristic maintenance lower waste and unplanned downtime.

- Sustainability: Professional resource allocation lowers carbon footprints across operations.

FAQs

- What are the biggest benefits of AI in supply chain management? AI helps the company with predictive decision-making, enhances visibility, and reduces operational risks. It does optimize demand forecasting, logistics, and supplier relationships for better profitability.

- Are AI tools affordable for mid-sized supply chain companies? Certainly. The AI solutions, such as o9 Solutions and FourKites, offer scalable subscription models. Cloud-based systems make more proactive AI accessible to SMEs without heavy infrastructure investments.

- How does AI improve supplier risk management? Many AI tools like Interos continuously analyze supplier data from multiple sources (financial, geopolitical, ESG) and provide early alerts on potential disruptions.

- Can AI help with sustainability in supply chains? Yes. AI helps sustainability by improving route efficiency, lowering energy consumption, and tracking suppliers’ ESG compliance.

- What’s the future of AI in supply chain management? The prediction of the future lies in autonomous supply chains, systems that self-correct, self-optimize, and make strategic decisions with minimal human intervention, powered by generative AI and advanced analytics.

Resources

- Gartner (2025): “Top Supply Chain Technology Trends in 2025.”

- IBM – Sterling Supply Chain Intelligence Suite

- Blue Yonder – AI-Driven Supply Chain Solutions

- SAP – Integrated Business Planning (IBP)

- Coupa – Supply Chain Design & Planning (formerly Llamasoft)

- Interos – AI Supply Chain Risk Platform

- FourKites – Real-Time Supply Chain Visibility

- o9 Solutions – Digital Brain for Supply Chains

- Project44 – End-to-End Supply Chain Visibility Platform

- Oracle SCM Cloud – AI-Driven Supply Chain Management

Author’s Bio:

Pankaj Tuteja

Head of Operations – India

https://www.dragonsourcing.com

What’s Happening i aam new to this, I stumbled upon this I have found It positively useful and it has helped me out loads.

I am hoping to gijve a contribution & aid different users likme

its helped me. Great job.