In today’s volatile economic landscape, procurement leaders are under constant pressure to cut costs while maintaining efficiency, compliance, and supplier quality. Whether you’re a procurement manager, supply chain director, or CEO, finding new avenues to save money without sacrificing performance is a strategic imperative.

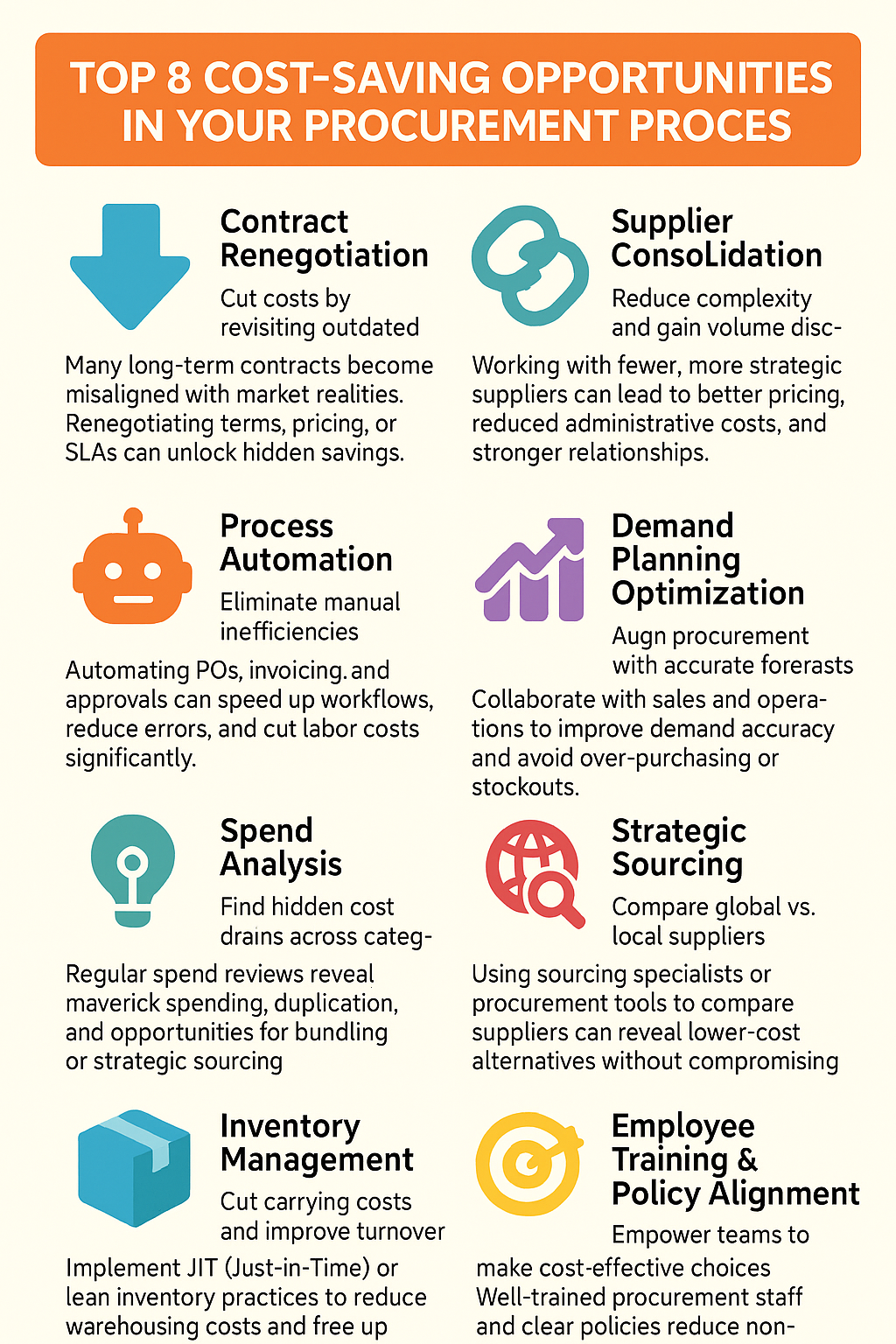

Here are the top 8 cost-saving opportunities that can significantly improve your bottom line when integrated into your procurement process.

1. Contract Renegotiation

Long-term vendor contracts often go unchanged for years—even when market conditions shift. Renegotiating terms like pricing, service levels, and payment conditions can uncover savings that were previously overlooked.

Tip: Conduct a regular contract audit every 12–18 months to identify renegotiation opportunities.

2. Supplier Consolidation

Too many vendors can lead to increased complexity, inconsistent pricing, and higher administrative costs. Consolidating your supplier base allows for volume discounts, streamlined operations, and stronger supplier relationships.

Tip: Identify categories with overlapping suppliers and assess potential for consolidation.

3. Process Automation

Manual procurement processes are prone to delays, human error, and inefficiencies. By automating functions such as purchase orders, invoice processing, and approvals, companies can significantly reduce labor costs and cycle times.

Popular tools: ERP systems, eProcurement platforms, and robotic process automation (RPA).

4. Demand Planning Optimization

Unplanned purchases often lead to emergency sourcing and inflated costs. Aligning procurement with accurate demand forecasts allows businesses to reduce excess inventory and avoid costly stockouts.

Tip: Collaborate closely with sales, operations, and logistics to build more accurate forecasts.

5. Spend Analysis

You can’t optimize what you can’t measure. Regular spend analysis helps uncover areas of maverick spending, duplication, and underutilized contracts—turning your data into strategic action.

Tip: Use spend analytics software to visualize cost breakdowns and identify outliers.

6. Strategic Sourcing

Strategic sourcing is more than just choosing the lowest-cost vendor—it’s about comparing suppliers globally, assessing total value, and mitigating risk. Companies that implement it often reduce procurement costs by 10–20%.

Tip: Evaluate both local and offshore suppliers with a total-cost-of-ownership (TCO) lens.

7. Inventory Management

Carrying excess inventory ties up working capital and increases warehousing costs. Lean inventory strategies like Just-In-Time (JIT) or Vendor-Managed Inventory (VMI) can improve turnover while minimizing waste.

Tip: Regularly review stock levels and turnover ratios to optimize reordering processes.

8. Employee Training & Policy Alignment

Procurement policies are only effective if your team understands and follows them. Investing in training and aligning employees with cost-saving goals ensures smarter buying behavior and better compliance.

Tip: Develop procurement playbooks, training sessions, and KPI-driven performance reviews.

Final Thoughts

Cost savings in procurement don’t come from a single tactic—it’s a combination of data-driven decisions, streamlined processes, and empowered teams. By focusing on these 8 key areas, businesses can unlock significant value and build a more agile, efficient procurement function.

If you’re looking to elevate your procurement strategy or implement automation and spend analysis tools, now is the time to act.

Author’s Bio:

Pankaj Tuteja

Head of Operations – India

https://www.dragonsourcing.com